Manufacture Of Organic Compost Using Arduino Technology

- JYP Admin

- Oct 1, 2024

- 5 min read

Updated: Oct 2, 2024

Authors: Mariam Moustafa and Nour Hassan

Summary

The world faces the dual challenges of developing productive crops and managing waste, which contributes to greenhouse gas emissions and climate change. This article addresses these issues by accelerating organic waste decomposition through an in-vessel composting process, producing high-quality organic compost that enriches soil and agricultural land. The project utilizes an integrated Arduino system, comprising sensors, devices, and code, to control temperature, moisture, and ventilation. By doing so, it reduces decomposition duration by over 50% compared to traditional methods. This innovative approach offers a cheaper, healthier, and more environmentally friendly alternative to traditional fertilizers, benefiting farmers, the economy, and the environment.

Introduction

Climate change is one of the most pressing issues of our time, with far-reaching consequences for the environment, economy, and human health. The increasing levels of greenhouse gases in the atmosphere, primarily due to human activities, are leading to rising temperatures and altered weather patterns. In this context, sustainable agricultural practices are crucial for mitigating the effects of climate change.

The aim of this study is to explore the potential of composting organic waste using Arduino sensors to monitor and optimize the decomposition process. This innovative approach can help reduce waste management costs, produce nutrient-rich fertilizers, and promote productive crops.

The importance of this study lies in its potential to contribute to a more sustainable and environmentally-friendly agricultural sector. By developing a cost-effective and efficient method for composting organic waste, we can reduce the environmental impact of agriculture while improving crop yields and promoting food security.

Methods

In our methodology for the project, three stages were followed:

Stage 1: Constructing galvanized steel and blades

Galvanized steel is the special box in which the whole the system will be put, so it has to be built with a special design and specifications that suit the conditions of the project. After creating its design, we deal with the blacksmith's workshop to build it, considering the installation of the shaft and the seven blades inside it.

Stage 2: Installation of the Arduino system

The 12V 70W water pump was connected with the 3V/3.3V high-level relay and the electric supply. Then, the relay was also connected to the electric supply and the Arduino UNO R3 board. The soil moisture sensor and temperature sensor were connected to the Arduino UNO R3 board. In the previous steps, the sensors were connected appropriately with the water pump, Arduino board, and the electric supply. The electric heater was connected to the system using a 12V relay that controls its electricity and connects it with the Arduino board and the whole system; in this case, we could control the electric heater with the code. The blades were connected to the DC motor to control their movement.

Stage 3: Creating the Arduino code to control the whole system

A C++ Arduino code was created to utilize the specific measurements of sensors we need for the perfect decomposition process, which are temperature 60 degrees Celsius (Compost Standards, n.d.) and moisture 60%. As the soil moisture sensor is connected to the water pump, the water pump decreases or increases the moisture to reach 60%. The electric heater is connected to the temperature sensor, it decreases or increases its temperature to 60 degrees Celsius. In addition, we use the code to control the duration of the movement of the steel blades by the DC motor, as it moves every 3 hours to provide suitable ventilation to the compost and mix the organic wastes continuously.

Results and Discussion

Three trials were carried out, as described below. There was a clear difference between all trials; the effect of both moisture and temperature on the duration of decomposition varied significantly. During the test plan, we made two attempts to achieve the best result. In each attempt, we collected several statistics and results and used mathematical operations to obtain the most accurate outcome.

Figure 1: Relation between three trails

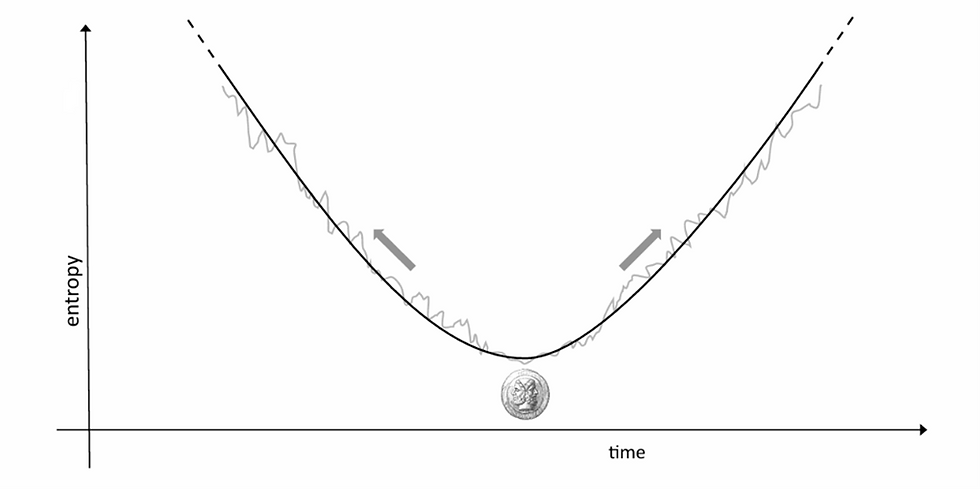

In the first trial, we relied on the sun's temperature, which has an average of around 32 degrees Celsius and the weather’s temperature with average 34%. However, the analysis took three months, which was a substantial amount of time. Later in the second trial, we used a temperature sensor to measure the compost temperature, and an electric heater was used to control the temperature, adjusting it to approximately 60 degrees Celsius. This modification reduced the analysis time from three months (12 weeks) to 7 weeks without considering the impact of moisture which shows the relation between the temperature and the decomposition duration, as the temperature increases the decomposition time decreases (inversely proportional) until it reaches 60 degrees. If the temperature is increased beyond 60 degrees, the bacteria die, and the decomposition duration starts to increase again, as shown in Fig 2, due to lesser bacteria available for decomposition.

Figure 2: Relation between temperature and decomposition duration

To create a suitable environment for the bacteria responsible for decomposing the organic wastes, moisture plays an important role. To measure the moisture in the decomposition medium, we added a soil moisture sensor in the third trail. The moisture is inversely proportional to the decomposition time; as the moisture increases, the decomposition duration decreases until it reaches 60%. If the moisture level exceeds 60%, it can kill the bacteria present in it, which can slow down the decomposition process (Fig 3). Therefore, the moisture sensor helps to know the current moisture and sets it at the appropriate level to speed up the decomposition time even more, which reduces the period from 7 weeks to only 3 weeks.

Figure 3: The relation between moisture and decomposition time

Figure 4: The decomposition process

Figure 5: The material and cost (in Egyptian Pounds)

Food wastes used included apple and banana peels, rice straws, eggshells, and other organic waste.

Conclusions

Organic compost is one of the most useful types of fertilizer that benefits the soil and crops and saturates them with minerals. In addition, it is the best for the economy, as it is lower in cost than any other compost due to its reliance on organic waste as a raw material. However, some challenges hinder its manufacture, the most important of which is the duration of decomposition of organic compost. This study addresses this problem and aims to significantly accelerate the decomposition process, as it takes into account all the factors that affect the duration of the decomposition, most notably moisture and temperature. This is achieved through an integrated Arduino system that controls these factors and monitors them. On running three different trials, it was concluded that the Arduino system reduced the time of decomposition to more than half the time it takes without the Arduino system; controlling temperature can reduce the duration from 12 weeks to 7 weeks and controlling moisture can reduce the duration from 7 weeks to 3 weeks. Therefore, we conclude that controlling both factors moisture and temperature appropriately can significantly reduce the duration of decomposition of organic waste and thus the manufacture of organic fertilizer is faster and with high quality.

References

[1] Pare, Mansi and Mohd, Aman. “Design of Organic Compost Machine.” International Research Journal of Engineering and Technology. Vol. 06, December 2019. https://www.irjet.net/archives/V6/i12/IRJET-V6I1264.pdf

[2] Organic Materials Review Institute. “Compost Standards,” n.d. https://www.omri.org/compost-standards

[3] Brinton, William F. “Compost Quality in America,” 2000. http://compost.css.cornell.edu/Brinton.pdf

[4] “Compost from organic solid waste: Quality assessment and European regulations for its sustainable use.” Resources Conservation and Recycling Vol. 94 (January 1, 2015): 72–79. https://doi.org/10.1016/j.resconrec.2014.11.003

.png)

Comments